When maintaining and servicing critical electrical equipment, safety, and performance are key. Saf Non-Flash, a cutting-edge, non-flammable solvent from Safic, is designed specifically for environments where electrical safety and effective cleaning are paramount. Its quick-drying properties and powerful cleaning action make it a trusted choice for industrial and electrical applications.

What is Saf Non-Flash?

Saf Non-Flash is a non-flammable, high-performance solvent, particularly effective for cleaning electrical components. It is formulated using a blend of chlorinated hydrocarbons with low toxicity, making it both powerful and safe for use around electrical equipment. Saf Non-Flash is designed to leave no residue, ensuring that it cleans without compromising the integrity or function of sensitive components.

Key Features of Saf Non-Flash

Non-Flammable: One of the standout features of Saf Non-Flash is its non-flammable nature. This makes it ideal for use in environments where electrical fires are a risk, such as substations, switchgear rooms, and around high-voltage equipment.

Non-Conductive: Saf Non-Flash has excellent non-conductive properties, with an electrical strength of over 75,000 volts per centimeter, making it safe to use on live electrical components.

Quick Drying: With quick evaporation rates, Saf Non-Flash ensures minimal downtime during cleaning procedures. This allows for efficient cleaning without leaving behind any moisture or residues that could affect equipment performance.

Effective Cleaning: The solvent is highly effective at removing carbon, dirt, oils, and other contaminants that may accumulate on electrical components over time.

Why Saf Non-Flash is Ideal for Electrical Equipment Maintenance

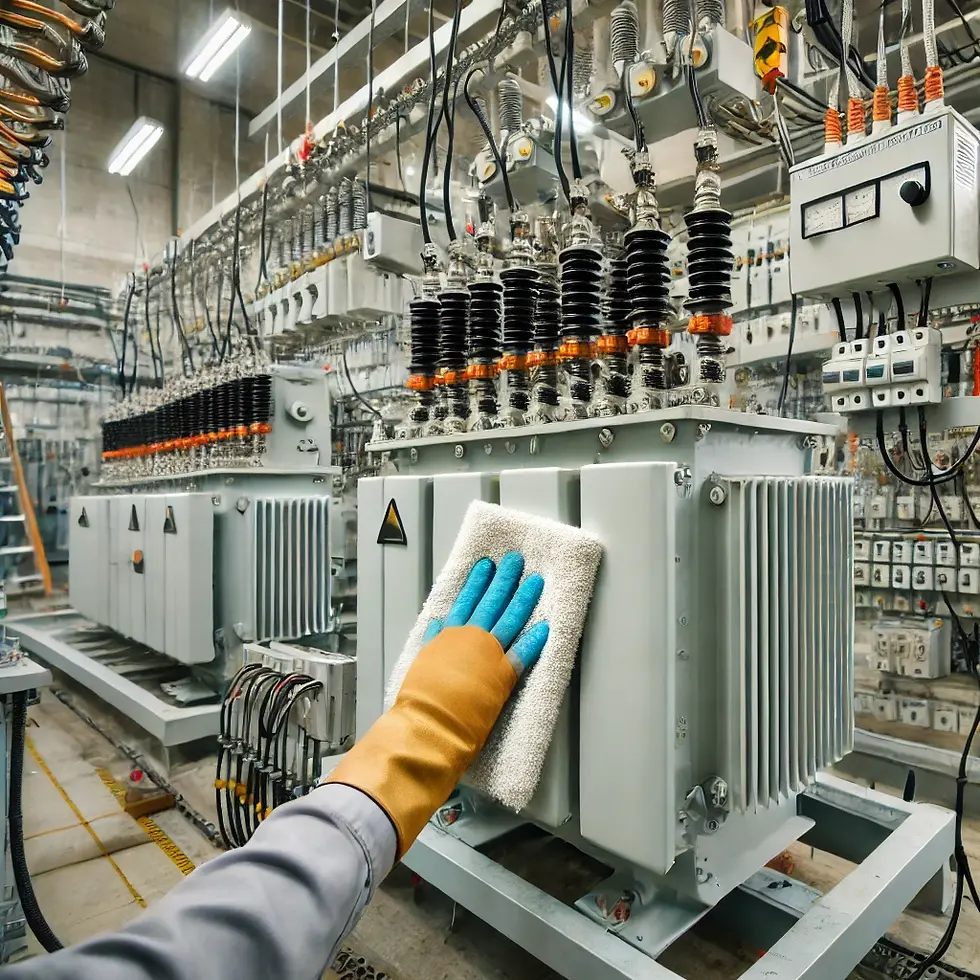

Electrical systems, especially critical ones like transformers, circuit breakers, and motors, require regular cleaning to maintain performance and prevent failures. However, traditional cleaning solutions often pose fire hazards or leave residues that could lead to malfunctions. Saf Non-Flash addresses these concerns by offering a non-flammable, residue-free cleaning experience.

When dealing with electrical equipment, any residue left behind could cause conductivity issues or attract further contaminants, leading to equipment failure. Saf Non-Flash evaporates completely, ensuring that no film or residue is left on the surface, making it ideal for equipment like switchboards and transformers.

Safe and Easy Application

Using Saf Non-Flash is simple and effective. Here are the recommended steps:

Preparation: Begin by blowing off any loose debris or dust from the equipment using compressed air.

Application: Apply Saf Non-Flash directly to the equipment using a spray. For more detailed parts, the solvent can be used in a dip tank. Allow the solvent to penetrate and dissolve dirt, oils, and carbon residues.

Drying: Allow the solvent to evaporate naturally, which happens rapidly due to its quick-drying properties. The equipment will be left clean, dry, and ready for operation.

Where to Use Saf Non-Flash

Saf Non-Flash is suitable for a wide range of electrical maintenance applications, including:

Transformers and Switchgear: These components are critical for electrical distribution and require safe, non-conductive cleaning solutions.

Motors and Generators: Carbon build-up and oil residues are common in motors, and Saf Non-Flash effectively removes these contaminants without damaging insulation or affecting electrical performance.

Control Panels: Saf Non-Flash can be safely used to clean sensitive control panels, ensuring optimal operation without the risk of short circuits.

Conclusion

Saf Non-Flash is the ultimate solution for safe, efficient, and effective cleaning of electrical equipment. With its non-flammable and non-conductive properties, it allows technicians to maintain critical systems without compromising safety. Whether used in substations, control rooms, or on industrial motors, Saf Non-Flash ensures the job is done right without risk.

Comments